What Seven Factors Separate Valve Service Shops?*

- OEM Authorized

- Asset Management Tools

- Certified Technicians

- Diagnostic Capabilities

- Access to OEM Inventory

- Technological Expertise

- Facilities

Together these seven factors determine the quality of your valve service at the many options within the marketplace. As companies increasingly turn to outside vendors, such as Setpoint Integrated Solutions, to manage their valve population, it is necessary to understand all the factors that can affect the quality of maintenance and repair.

Factor 1: OEM Authorized Repair

One territory can have dozens of firms that offer valve maintenance and repair services. All of these firms are not created equally. Often times the experience can be described as:

” Valves coming back from the repair shop looked great. Testing, however, told a different story. Many of the valves have not been repaired correctly and are not performing to OEM requirements.”

This usually results in higher maintenance costs and/or lost production. It also can mean compromised product quality and unnecessary safety risks. In order to ensure repeatable quality and minimize these safety risks, working with OEM Authroized Repair Facilities is integral.

To diagnose control and line valves, the shop should have a unit that can compare current valve data to “Day One” baseline data.Most valve OEMs have a list of authorized service providers. No one is required to choose one of these providers, but the credential of being listed as authorized is one sign of a quality shop.

To become an authorized service provider, a shop must meet specific criteria the OEM sets in areas such as integrity, safety and environmental compliance. Plus, the team is required to complete the OEM’s training program. Usually, OEMs hold certified shops to high standards when it comes to facilities, equipment and personnel. Knowing that a service provider meets these criteria, however, gives companies added confidence that they are dealing with a reputable shop.

OEMs regularly audit their authorized service providers to ensure they are meeting the necessary performance standards. While ISO 9000 is a good standard to be followed, it is not a valve operating guideline. When it comes to valve assembly/testing and repair, the OEM is the body best equipped to conduct the detailed review necessary and is willing to share audit reports.

Additionally, OEM-authorized service providers have access to important details regarding the properties, construction and workings of a specific valve or part. This is because OEMs build their products to rigorous specifications. While it’s true that a valve or part can be re-engineered, only the OEM knows the original specs with certainty.

An OEM-authorized service provider also receives extensive product training from the OEM and can consult with the OEM’s engineers to diagnose problems. An authorized shop will use OEM parts, rather than re-engineered parts, helping to ensure that the valve performs as expected.

Finally, not using an OEM-authorized service provider may void the manufacturer’s warranty.

Setpoint Integrated Solutions is an OEM-authorized service provider. Specific certifications held across our branch locations are: Masoneilan Authorized Repair Center (MARC), Consolidated Green Tag Center (GTC), Groth Authorized Repair Dealer (GARD), Flowserve Black Tie Authorized Repair House, Valve Automation and Control Repair Facility. Details found here.

Factor 2: Asset Management Tools

A significant differentiator between valve service shops today is the ability to provide asset management tools. These tools put valve records—including repair data, repair records, test documentation, wiring diagrams and “before” and “after” photos”—in a single, easy to use, accessible database. The customer owns the data and can access that information 24 hours a day.

This added capability can simplify record-keeping for inspections and make it easier to meet reporting requirements. But asset management tools can be so much more than just a document management tool—they can be a plant manager’s best friend. Some, for example, provide analysis features and can assist in detecting trends for repairs, some manage inventory for optimization, others provide features such as “turn-around management” clouds where one can drag and drop valves for planning a turnaround. Others help with diagnostics and provide recommended solutions for resolving issues.

Setpoint Integrated Solutions, in collaboration with Baker Hughes, a GE Company, utilizes ValvKeep for all the valves it touches. ValvKeep tracks each repair event for each valve that goes through our shops. This information is then used, similar to a medical record, to track the health of the valve throughout its lifetime. More information found here.

Factor 3: Certified Technicians

When a person chooses a physician, he or she is likely to consider degree of education, specialized training and other credentials. The same criteria should apply when choosing a valve service partner. Those choosing should ask to see a firm’s training certificates; and find out whether the technicians are trained in the latest OEM standards, as well as relevant standards from organizations such as the American Society of Mechanical Engineers. They also should ask whether the technicians’ certificates are up-to-date because training is not a one-time task, but a continuous process.

With more than 200 certified and nationally accredited technicians, Setpoint Integrated Solutions stands ready to serve your needs through process repair services. Setpoint I.S. is committed to the highest standard of safety and quality assurance.

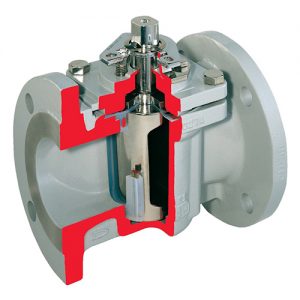

Factor 4: Diagnostic Capability

To diagnose pressure relief valves, technicians should have electronic valve testers that can test a valve in-situ.Today, when your car has an odd noise, your mechanic uses computer-based tools to diagnose the problem. A solid valve service provider will have similar tools in its collection.

For example, a technician working with pressure-relief valves should have electronic valve testers that can test a valve in-line and in production (in-situ). For control and line valves, technicians should have a diagnostic unit that can compare current valve data to “Day One” baseline data. With a significant number of analog positioners still in use, such devices can help remove the guesswork from assessing valve health.

Setpoint Integrated Solutions Technicians are OEM certified and highly trained. Their use of diagnostic tools save you time and money by making the right repair the first time.

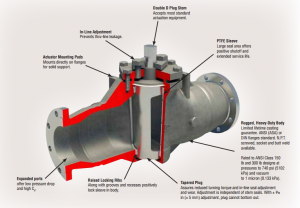

Factor 5: Access to OEM Inventory

A good service provider has OEM valves and parts in stock and can quickly configure, assemble and test a replacement valve.Even the best technician cannot get a process running again without the necessary parts, replacement valves and other devices. When something is needed to get that process going, the best providers of maintenance and repair services will simply pull from their well-stocked shelves the necessary OEM parts, valves, positioners, etc.

Certainly, it is impossible for a service provider to have every SKU in its warehouse. But affiliation with a network of service facilities can provide access to millions of dollars of inventory that can be on hand in days, and sometimes even hours. A prospective service provider needs to belong to such a network.

Setpoint Integrated Solutions carries significant inventory for all of the OEM partners that it represents.

Factor 6: Technological Expertise

A growing number of facilities are adopting digital technologies such as wireless communication, valve diagnostics, the HART Protocol, the FOUNDATION fieldbus and PROFIBUS. A strong service provider will have a “digital champion” on staff or accessible who can guide users and who has the technical expertise to advise on when to upgrade to digital technology.

Setpoint Integrated Solutions focuses on providing best in class technological expertise through the aforementioned protocols as well as the use of other systems such as ValvKeep, VavleAware, and Valve Vue.

Factor 7: The Facilities

Visit a prospective service provider’s facility. Take note of whether the shop is neat, clean and well-lit. Organization is strongly correlated to quality. This photo shows the DMC–Carter Chambers facility in LaPorte, Texas.A tour of a prospective service provider’s facility can reveal much. Such a tour should include stops at areas in the shop for sandblasting, machining, welding and painting. Take note of whether the shop is neat, clean and well-lit; organization of that shop is closely correlated to quality. After all, would anyone hire an accountant whose office was wall-to-wall stacks of paper? As an added benefit, some providers also have onsite facilities where they offer training for their customers.

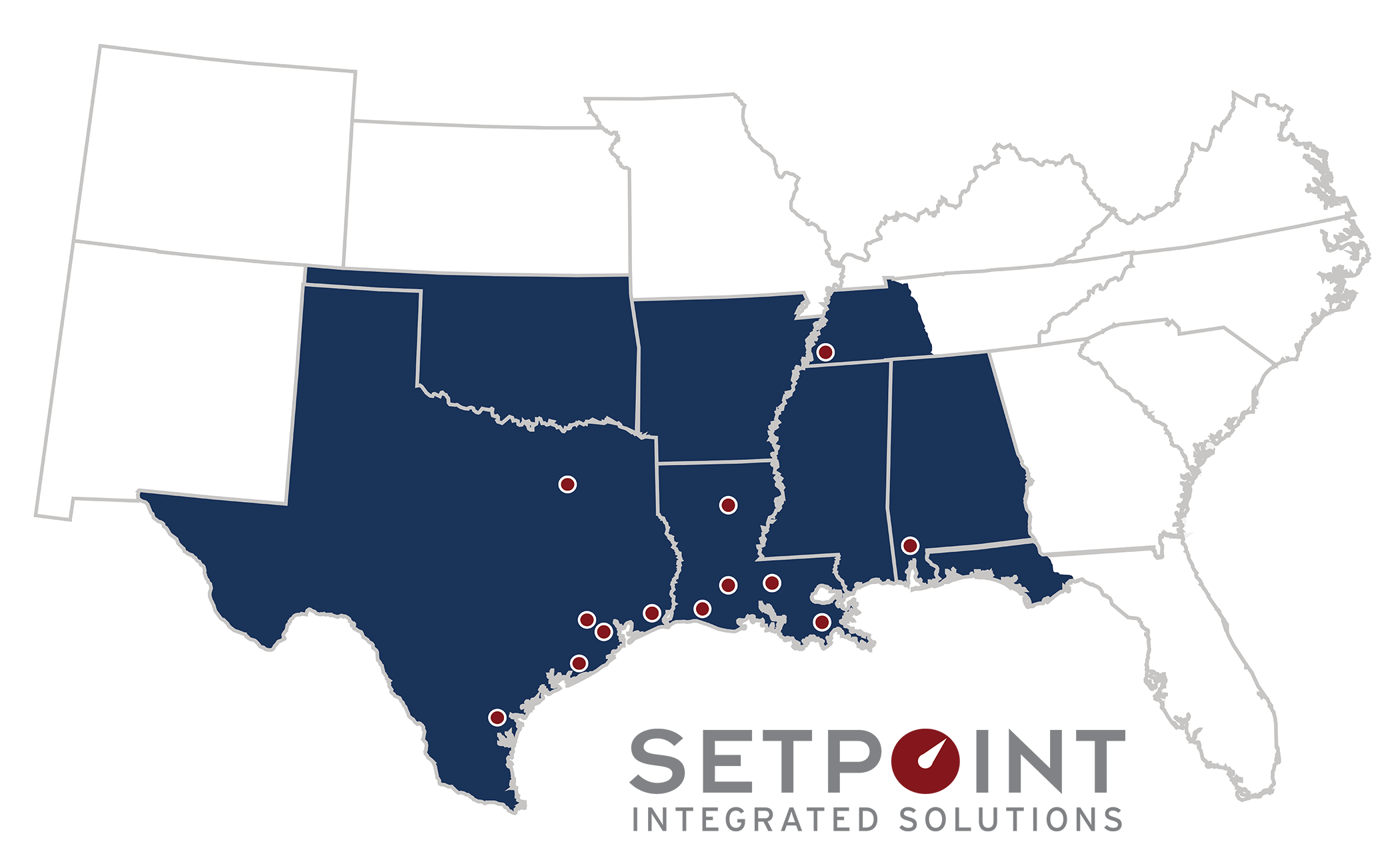

State-of-the-Art Facilities: Setpoint I.S. features more than 400 employees and encompasses more than 425,000 sq. ft. of repair and distribution facilities across 13 strategic Gulf South locations. We’ve invested in the latest technologies and equipment to ensure our customers receive the best service available.

Choosing a valve service provider requires time and effort. But given the importance of valves to any process facility’s performance, the decision cannot be taken lightly. The key is: Do your homework; it will be time well spent.

Setpoint Integrated Solutions stands ready to assist in all your valve service and valve repair needs. Contact us today.

*This Content was adapted from an article by Gary Ostrowksi for Valvemagazine.com found here.

Celebrating its 35th Anniversary this year and featuring a Setpoint Integrated Solutions full page ad in the commemorative anniversary issue below, the Baton Rouge Business Report hosts many events in the community. At the most recent event, the Top 100 Private Companies in Baton Rouge were all honored at a luncheon at the Baton Rouge Crowne Plaza.

Setpoint I.S. was the 28th largest private company in Baton Rouge by 2016 revenue.

At the luncheon, report by Baton Rouge Business Report found here, economist Dr. Loren Scott delivered his annual Louisiana Economic Outlook. Across the Setpoint Integrated Solutions footprint, the Industrial Boom continues. Setpoint I.S. views this report as a positive indicator for growth and stands ready to meet our customer’s needs.