What Are the Characteristics of Ball Valves?

What are the characteristics of Ball Valves? *

Ball Valves, like the previous post on Plug Valves, are a type of quarter turn isolation valve.

The most common design that is utilized features a ball that rotates between two circular seats which are usually made of some type of PTFE , co-polymer, or other resilient plastic material. When this type of ball valve is in the open position, media flows through the opening in the ball, and when closed the flow is completely blocked. Ball valves are often used for On/Off service (isolation) and are suitable for Bi-Directional Flow.

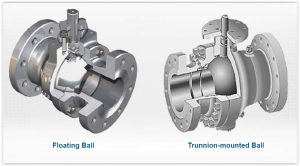

There are two types of ball valves, Floating Ball Valves and Trunnion Mounted Ball Valves.

Floating Ball Valves

Floating Ball Valves feature a ball that floats between the two seats and uses line pressure to push the ball downstream for a positive closure. Floating Ball Valve Characteristics include:

- No lower stem, providing savings during constrution

- Relatively small size range, typically from 1/2″ – 12″

- Tight sealing ability via the ball on the seat

- Low operating torque

- Downstream sealing only

Floating ball valves will provide tight seating with low torque, while being well suited to multi-port applications.

A variety of ball valve configurations also exist, with one piece flanged, two piece flanged, two piece threaded, and three piece threaded options available.

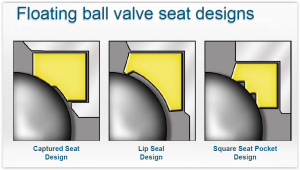

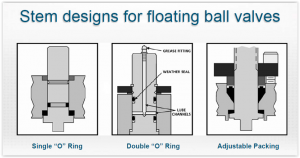

Additionally, Floating Ball Valves have different seat designs and stem designs.

Trunnion-Mounted Ball Valves

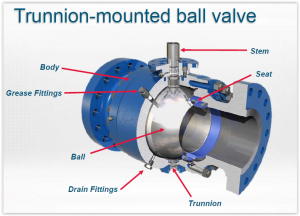

A Trunnion-Mounted Ball Valve uses a Trunnion, or lower stem to support the ball within the valve body. Characteristics of a Trunnion-Mounted Ball Valve are:

- The ball is fixed, it does not float

- The ball is centered by the stem at the top and trunnion at the bottom

- The seal is formed by the seats moving toward the ball

- More complex than floating ball valves

The Trunnion-Mounted Ball Valve is made up of the following basic components. Body, Ball, Seat/Seat Assemblies, Upper Stem, Trunnion and End Connections. These valves are often supplied with flanged or butt-weld ends.

The advantages of Trunnion-Mount Ball Valves are:

- No size limit to the use of trunnion-mounted ball valves

- Trunnion supports the weight of larger balls

- May be used in higher pressure applications

- Seat Moves to the Ball

- Lower Torque and Actuation Costs

- Ease of Operation

- Double Block and Bleed Capabilities

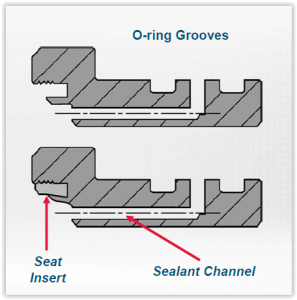

The Trunnion seat design is manufactured in one operation that machines the metal seat holder / retainer to which the seat insert is added. In some configurations the seat insert is then locked into place by rolling the seat lip into the insert groove, resulting in an extremely reliable seal.

Applications

Ball Valves are used in a variety of applications including, but not limited to:

- Turbine Skids

- Compressor Skids

- Generator Skids

- Separator Skids

- Field Gas Plants

- Crude Oil Plants

- Gas Feed Lines

- Polymer Plants

- Automated Process Applications

- Industrial Gas Processing Plants

- LNG Plants

- Hydrocarbon Processing

- Tank Farms

- Oil Refinery Feed Stock Lines

Setpoint Integrated Solutions has a variety of both floating and trunnion-mounted ball valves available from top tier OEM partners. Contact us today.

*This post was adapted from content created by VMA at their Valve Basics Course, found here.