What are the Characteristics of Quarter-Turn Isolation Butterfly Valves?

Continuing with the previous posts regarding Quarter-Turn Isolation Valves with a post about the characteristics of Butterfly Valves. Like the Plug and Ball, the Butterfly Valve saves weight and is faster to open and close, but it also saves space. * This article will focus on Resilient Seated design. There are also Double Offset and Triple Offset Butterfly Valves, which will be explored in a forthcoming post.

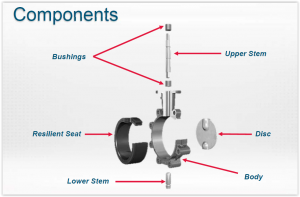

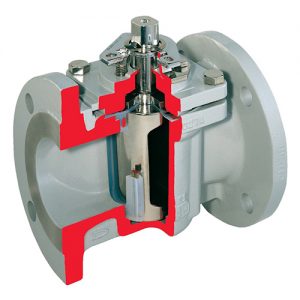

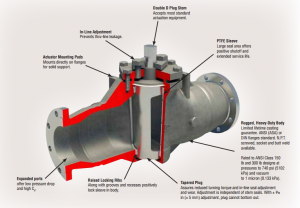

Butterfly Valves are designed so that the fluid is controlled by a disc, rather than a plug or ball, which helps save space. It can have a resilient seating design. This design incorporates a disc that is held in the center of the valve and rotates to control product flow. The disc is always in the media stream with minimal flow restriction. Resilient seated butterfly valves are not ANSI‐rated but fit between ANSI Class 125 & Class 150 flanges.

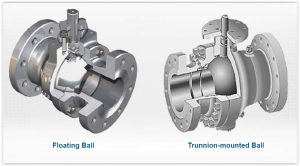

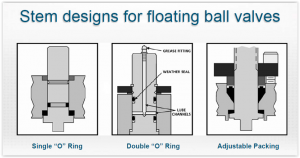

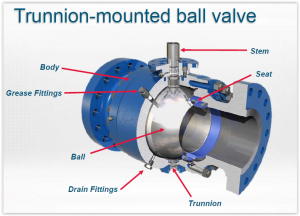

Most butterfly valves use the same basic stem configuration as a trunnion‐mounted ball valve with a stem on the top and bottom. However, in this case the stem is mainly incorporated to balance the disc. Many different types of seat materials are available, including Buna (NBR), EPDM, Viton (FKM), PTFE, natural rubber or neoprene.

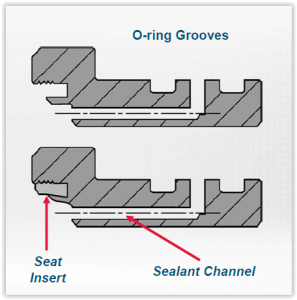

The seat shown above is a cartridge type seat; it has a phenolic backing ring with the elastomeric seating material molded to it. Other types of seats are booted and molded.

Both the cartridge and booted type seats can be replaced along with other critical parts.

Elastomers are excellent for a broad range of services, except steam.

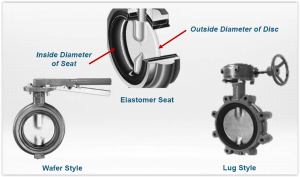

There are a variety of butterfly valve styles based on how they are mounted in a piping system. The wafer style fits between two flanges and bolts surround the valve. The lug style has protruding lugs with tapped bolt holes mating it to standard flanges. The lug style butterfly valve is commonly used in dead‐end service. Both wafer and lug style valves do not need gaskets when mounting them in the piping. Then there is the flanged style. It has two end flanges and is bolted up just like any other flanged end valve. Another type is the grooved end butterfly valve. The grooved end design has a longer face to face, like the flanged, but is much faster to install.

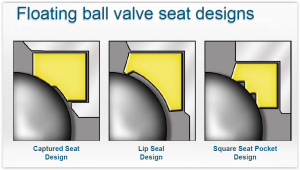

The basic elastomer‐seated butterfly incorporates an interference fit where the disc diameter is slightly larger than the seat, which provides a bubble‐tight seal. The shut‐off capability is solely a function of this interference and greatly affects the torque. The primary stem seal is also an interference fit. With the improvement in elastomer technology and the introduction of many new elastomers, the performance of butterfly valves has improved. These butterfly valves are well suited for on/off and throttling applications. They are available in 2‐inch through 72‐inch sizes.

There are many materials that can be used for the body, stems, disc and seats. Some options for the body include various irons, bronze and steels. Stems are often made from 316 or 416 SS, and Monel. Discs use aluminum bronze, ductile iron or alloy 20, to name a few. We previously mentioned the most common elastomers. Take care when selecting the seat material. The user should be familiar with temperature limitations and compatibility of the elastomers for the intended service.

- Bodies:

- Ductile Iron

- Cast Iron

- Aluminum

- Bronze

- Carbon Steel

- Aluminum

- Stainless Steel

- Stems

- 416 SS

- 316 SS

- Monel

- Discs

- 316 SS

- Monel

- Aluminum

- Bronze

- Ductile Iron (NP)

- Ductile Iron (PVF coated)

- Alloy 20

- Hastelloy C

- Seats

- Buna-N

- Black Neoprene

- Hypalon

- Viton

- Peroxide cured EPT

- natural rubber

- White Neoprene

- ETM-30230

- Fluorosteam

- Peroxide-cured food grade EPT

- Peroxidecured Buna-N

- Sulfur cured food grade EPT

Butterfly Valves can be utilized in a variety of applications. The HVAC industry is one of the biggest users of butterfly valves. Other industries include chemical, petrochemical, refining, irrigation, and oil and gas drilling. Butterfly valves are also commonly found in food and beverage applications, water and wastewater, power generation, mining and dry bulk handling.

Setpoint Integrated Solutions offers a variety of butterfly valves that will suit any application. We are proud to partner with Flowserve Durco and Triac brands. Contact us today to find out what configuration works best for you.

*This post was adapted from content created by VMA at their Valve Basics Course, found here.

Celebrating its 35th Anniversary this year and featuring a Setpoint Integrated Solutions full page ad in the commemorative anniversary issue below, the Baton Rouge Business Report hosts many events in the community. At the most recent event, the Top 100 Private Companies in Baton Rouge were all honored at a luncheon at the Baton Rouge Crowne Plaza.

Setpoint I.S. was the 28th largest private company in Baton Rouge by 2016 revenue.

At the luncheon, report by Baton Rouge Business Report found here, economist Dr. Loren Scott delivered his annual Louisiana Economic Outlook. Across the Setpoint Integrated Solutions footprint, the Industrial Boom continues. Setpoint I.S. views this report as a positive indicator for growth and stands ready to meet our customer’s needs.