What Are the Characteristics of Quarter-Turn Isolation Plug Valves?

There are many choices of Quarter-Turn Isolation Valves within the industry, such as Plug Valves, Ball Valves, and Butterfly Valves. This post will focus on Plug Valves and their characteristics.*

• In the quarter-turn family, opens and closes with 90-degree rotary turn

• Used for on-off and regulating flow

• Lubricated and non-lubricated types

• Available in many different materials

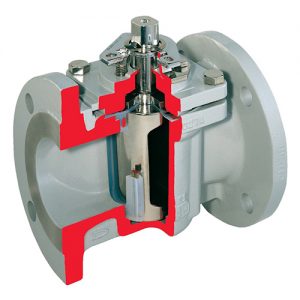

Plug valves have been in use for quite some time, they are the oldest design of the quarter-turn isolation valves. They contain three basic components, of a body, a plug, and a cover. The plug can be round, rectangular, tapered, or cylindrical, features a passage through which the media can flow, and this media flow will be controlled by turning the plug 90°, hence the term Quarter-Turn.

The on-off rotary turns will allow for isolation and for regulating flow.

While plug valves are useful in many applications, they are particularly easily adapted to multi-port construction. As a result, three and four way plug valves are commonly used in the chemical processing industry. An advantage of this is the elimination of fittings or multiple straightway valves with one multi-port valve.

Plug Valves can be classified into two types:

- Lubricated

- Non-Lubricated

Lubricated Plug Valves

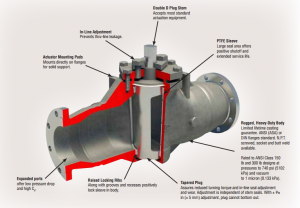

Lubricated Plug Valves allow lubrication to be injected in a fitting under pressure through grooves in the plug or body to prevent fluid leakage between the plug face, and the valve body. The reduced friction from the lubricant also enhances easy and quick operation of the valve. The lubricated plug valve seals only against the downstream seat, and when properly lubricated is often the most leak-free seal available. Temperature limits will be based on the lubricant used within the valve, and the pressure drop should be fairly low due to the flow path being streamlined.

Lubricated Plug Valves are often used in handling hydrocarbons, corrosive fluids, and slurries.

Non-Lubricated Plug Valves

Non-Lubricated Plug Valves have multiple different subgroups, comprised of Lift, Sleeved, Lined, Eccentric, and Offset Eccentric.

Lift type non-lubricated valves are designed so that the stem first lifts the plug off the seating surface and then rotates the plug into the open position. This is useful in extending the life of the plug as it is not being drawn against the seating surface during stroking. After rotating the plug to the closed position the handwheel will continue to need to be rotated until the plug is properly in position against the seat. The mechanical seal on both the upstream and downstream sides of the valve in the closed position allows this type of plug valve to be used as a double block and bleed. This feature allows the center section to bleed or clear any debris within the valve if it is has been equipped with a bottom access plate.

Sleeve lined plug valves are similar to a conventional plug valve, but it uses a fluorocarbon sleeve locked in place surrounding the tapered plug maintaining a continuous seal. THe sleeve supplies the lubricity needed to cycle the valve, giving it characteristics of quick open and close, maintenance free performance, non-stick, and an extended life.

A lined plug valve is the same as a sleeved plug except that the body and plug are completely plastic or teflon lined and this isolates the valve body from the media. Usually made with a body of Ductile Iron, which is sufficient due to low temperature and pressure used in chemical applications. Having the valve body isolated offers a less expensive alternative to special alloys. The limits on a plastic lined or sleeved plug valve is that it has a limited operating temperature, usually no more than 400 degrees F. These valves tend to be found in highly corrosive applications, pharmaceutical, and food / beverage applications.

Finally, the eccentric type of non-lubricated plug valves is similar to a conventional plug, with half of the plug being removed. As the plug rotates it is moved away from the seat, so that the plug is completely out of the media flow path when fully open.

Setpoint Integrated Solutions has a variety of Plug Valves to choose from, as we are distribution partners of top tier OEM Flowserve Durco.

*This information was adapted from content created by the Valve Manufacturers Association for Valve Basics, details found here.