Setpoint Integrated Solutions Holds Open House for Grand Opening of New Lafayette Location

FOR IMMEDIATE RELEASE

April 20, 2017 – Broussard, Louisiana, Setpoint Integrated Solutions (Setpoint IS) held the grand opening of its new 8,340 sq. ft. Lafayette Branch located in Broussard, La. on April 20, 2017. This location houses 7 employees and serves the Greater Lafayette area. The grand opening included a ribbon cutting ceremony with Mayor Thomas Nelson, St. Martin Parish Councilwoman Lisa Nelson, and Setpoint IS CEO Jack Guidry.

Jonathan Pledger, Vice President of the Eastern Region : “ The Greater Lafayette community has experienced very challenging times with the downturn in the oilfield market. Setpoint IS’s leadership wanted to tangibly demonstrate to our customers, our employees, our suppliers, and the community that we are here for the long term to meet the requirements of the upstream market. We saw no better way to do this than to invest in a new facility.”

OEM partners Schneider Electric, Turck, Scott Safety, and Ashcroft all exhibited at the celebration that followed, highlighting the Lafayette Branch’s commitment to distributing top tier products to its customers.

“We appreciate the support from our customers and vendors. We are happy to be a part the Oil & Gas Industry, despite the ups and downs of the market. We look forward to seeing an increase in business this coming year and can’t wait to cater to our customer’s needs for many years to come.” Mindy Delino, Lafayette branch manager.

About Setpoint Integrated Solutions

Setpoint Integrated Solutions (Setpoint IS) is a leading integrated solutions and services provider in the process control industry. Setpoint IS engineers, sells and services products ranging from control valves and process automation equipment to relief valves and industrial filtration, and provides a full range of site services and immediate technical support. Setpoint IS, headquartered in Baton Rouge, La., is a subsidiary of Pon Holdings B.V. of the Netherlands. For more information on Setpoint IS’ products, services and locations, please visit www.setpointis.com.

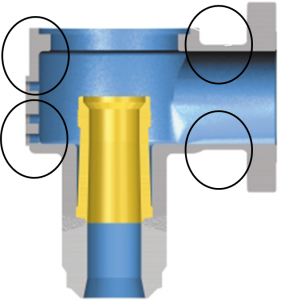

The circles identify areas in which body wall inspection may not be a requirement of the Valve’s repair process. The areas are the ones that Setpoint IS recommends reviewing to check if they adhere to ASME B16.34-2013 Table 3B.

The circles identify areas in which body wall inspection may not be a requirement of the Valve’s repair process. The areas are the ones that Setpoint IS recommends reviewing to check if they adhere to ASME B16.34-2013 Table 3B.