Features

- Our comprehensive portfolio of safety valves can help to run operations smoothly and cost-effectively, particularly in steam service environments.

- Consolidated safety valves feature a unique pop-action release that can relieve steam overpressurization if pressures upstream from the valve reach a set point

- Consolidated safety valves comply with the ASME Section I code for boiler applications.

- They are built with many features that meet ASME requirements for steam-compressible fluids. For example, all models feature a lifting lever, required by the code for testing, instead of deadweight or weighted levers. Consolidated safety valves can also withstand set pressures up to 103 percent with a blowdown value of 4 percent, or 96 percent of set pressure drop before

the valve re-seats.

High-Pressure & Steam Safety Valves

Setpoint Integrated Solutions offers many Safety Valves to meet your specific application needs. Highlighted below is our wide array of Consolidated Products

The Consolidated Type 1700 Maxiflow High Pressure Safety Valve is a premium product that is installed on a majority of power generating stations worldwide to protect boilers from over-pressure conditions.

The Consolidated Type 1511 Steam Safety Valve are designed for low-pressure steam heating boilers and steam generators as well as air service applications

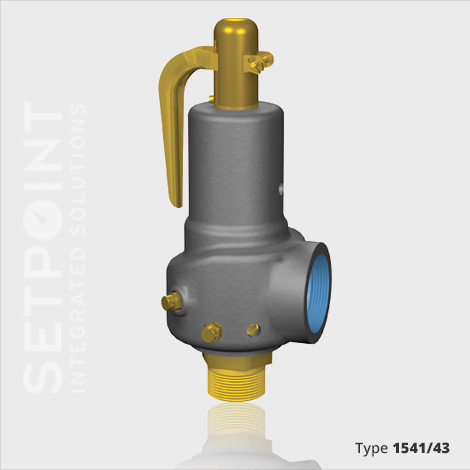

The Consolidated Type 1541/1543 Steam Safety Valve are designed for steam and other compressible fluids.

The Consolidated Type 1811 Steam Safety Valve is a cost effective, high capacity, flanged steel safety valve designed for steam service.

The Consolidated Type 2700 Steam Safety Valve is designed to meet the needs of the co-generation and waste to energy markets.

Contact Us

p. (225) 753-3290

e. info@setpointis.com