What are the Characteristics of High Performance Butterfly Valves and Triple Offset Butterfly Valves ?

What Are the Characteristics of High Performance Butterfly Valves and Triple Offset Butterfly Valves?*

Continuing to expound on the previous post on Resillient Seated Butterfly Valves ,this post will focus on the characteristics of Double Offset , also called High Performance Butterfly Valves, and Triple Offset Butterfly Valves.

What is a High Performance or Double Offset Butterfly Valve?

High Performance Butterfly Valves use a disc offset from the seat center, hence the name Double Offset.

In this configuration, the disc is eccentric, or offset, from the valve seat. As the disc starts to rotate, it moves away from the seat instead of across it. This design actually uses the line pressure to help give it its seal. This feature allows the use of offset butterfly valves in high‐pressure applications such as ethanol or HVAC. It generally uses PTFE or plastic as its seat material, but metal seats are also available to meet fire‐testing specifications like API 607.

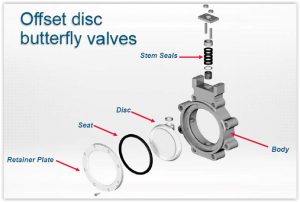

Offset Disc Butterfly Valves are comprised of the following components:

- Body

- Retainer Plate

- Seat

- Disc

- Stem

- Stem Seals

Standard double offset butterfly valves come with a polymer seat, usually PTFE, with a metal backup for fire safety. Metal‐to‐metal seats are also available and may provide a higher sealing quality, and allow slightly higher temperatures.

What is a Triple Offset Valve (TOV) ?

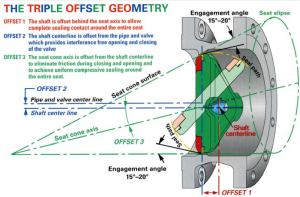

A triple offset valve is a torque‐seated valve. In addition to the standard components, the TOV has three offsets. Seats are made of a laminate of metal and graphite and are commonly field replaceable. This valve does not act like a normal butterfly valve that is seated by positioning the disc using a lever, gear or body stop. TOVs are similar to globe valves in that the disc acts like a cone being torqued into a circle seat. The only way to get a bubble‐tight zero leakage seal with a metal seat is to put a cone into a circle. Triple offset valves can be lug, wafer, flanged and butt‐weld. Class rated valves are available from various manufacturers and are manufactured in sizes up to 160 inches. TOVs are adaptable to a wide range of temperatures, from ‐420 to 1200 degrees F.

Because a triple offset valve has three offsets in the stem/disc alignment, its disc rotates 90 degrees with the last +/‐ 1 degree being a straightforward movement. The body seat of the valve is not a perfect cone; rather, it is “offset” and machined at an angle so the disc will match up with no rub when seating. A Stellite overlay ensures a hard seating surface. By tightening the handwheel the valve seats tighter into the seat, typically something only possible with gears. Unlike a gate, ball or high‐pressure butterfly valve, there is no drag across the seat when the disc contacts the seat.

As viewed from the top, the first offset is accomplished by positioning the stem off center to or behind the disc seating face. The second offset moves the stem off centerline of the pipe or valve opening. The third and final offset is the seat cone angle, which is machined into the valve body. When the valve disc is rotated there is no rubbing across the seat. These three offsets enable the TOV to accomplish zero leakage in a metal‐seated valve.

- Main applications for TOVs

- Steam-distributed (600# & below)

- Universities

- Hospitals

- Large buildings

- Government facilities

- Steam production plants

- De-icing/heating for plants

- Petrochemicals

- Coking

- Reformers

- Tank switching

- Ethylene

- Butadiene

- Isocyanates – plastics

- Tank and terminal

- Long pattern or gate valve replacement

- Storage of hydrocarbons and chemicals

- Upstream production

- Process equipment

- Separation

- Switching

- Floating production platforms

- Manifolds

- Slurry-tar sands

Setpoint Integrated Solutions offers a variety of high performance and triple offset butterfly valves that will suit any application. We are proud to partner with Flowserve Durco and Triac brands. Contact us today to find out what configuration works best for you.

*This post was adapted from content created by VMA at their Valve Basics Course, found here.